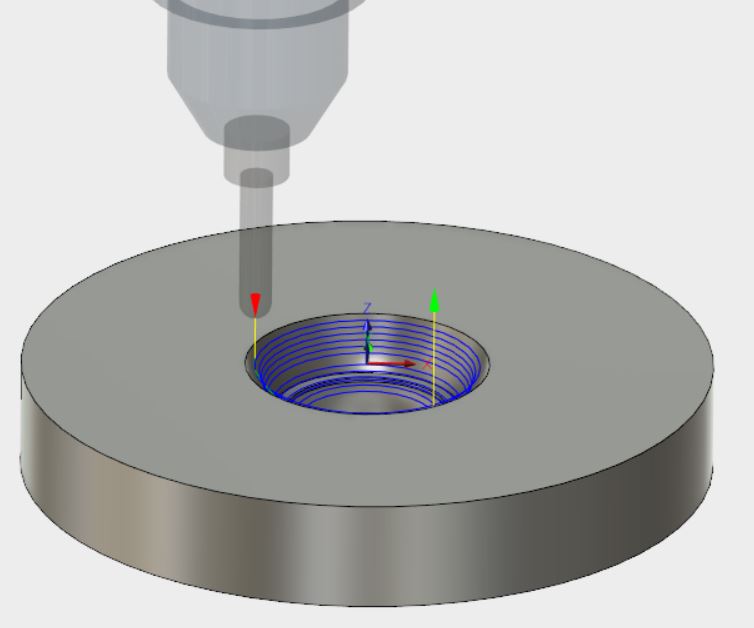

Hi, I’m curious if it is possible to efficiently mill a concave profile inside a hole. The application is a double J weld groove through a flange. A very typical groove design that is almost always drilled and turned on a lathe. I have attached a link of my F360 file that I’ve drawn up. I’ve used 3D adaptive, followed by other 3d or 2d profiles and can’t seem to clear all the material completely AND efficiently. The groove is the same on both sides, so just looking to figure out one side for now since it can be flipped and copied later. Does anyone have any ideas or experience milling this kind of feature? FYI I only have standard 3 axis mill available.

Double J Groove

Thanks,

Derek

1 Like

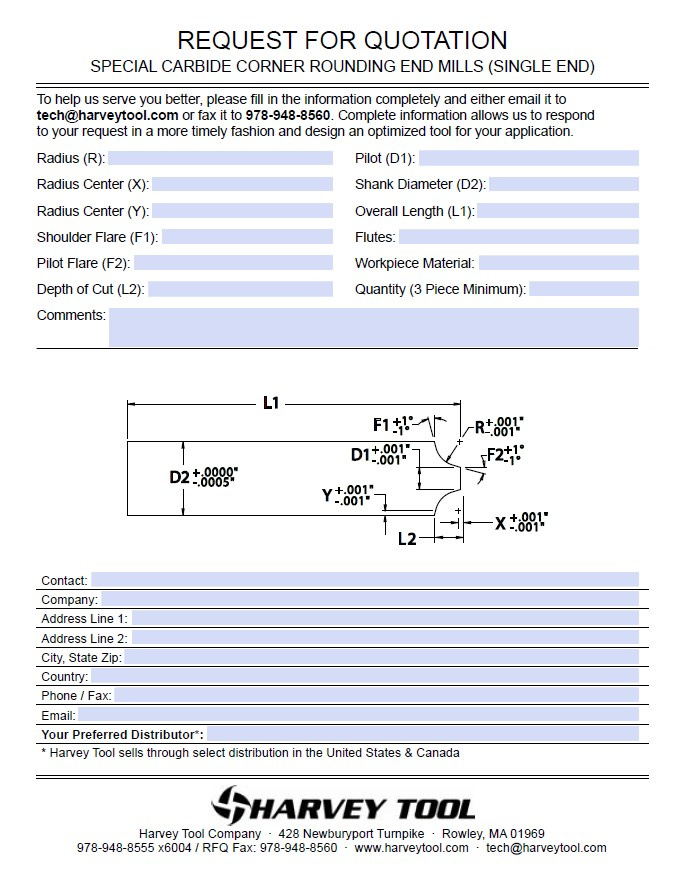

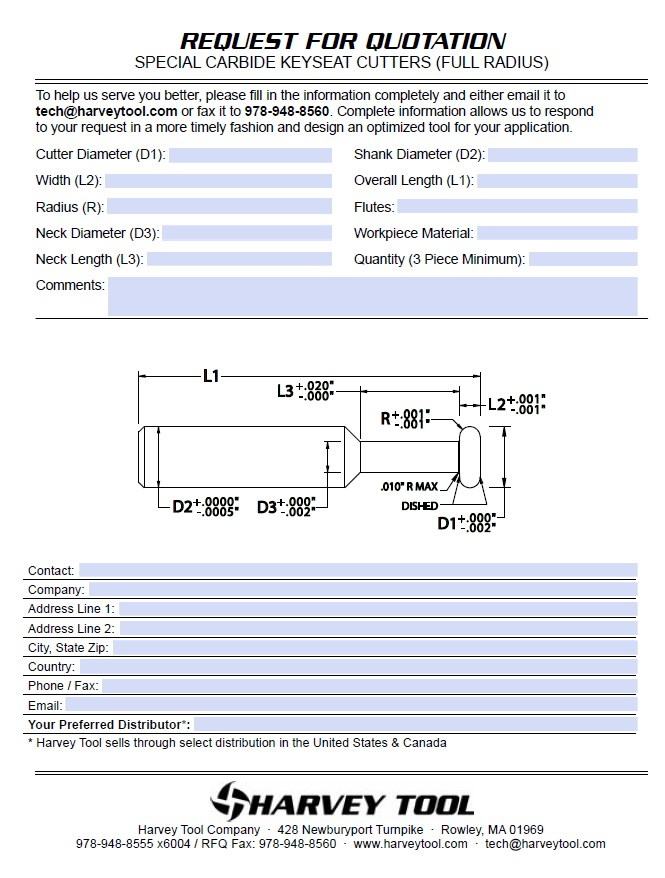

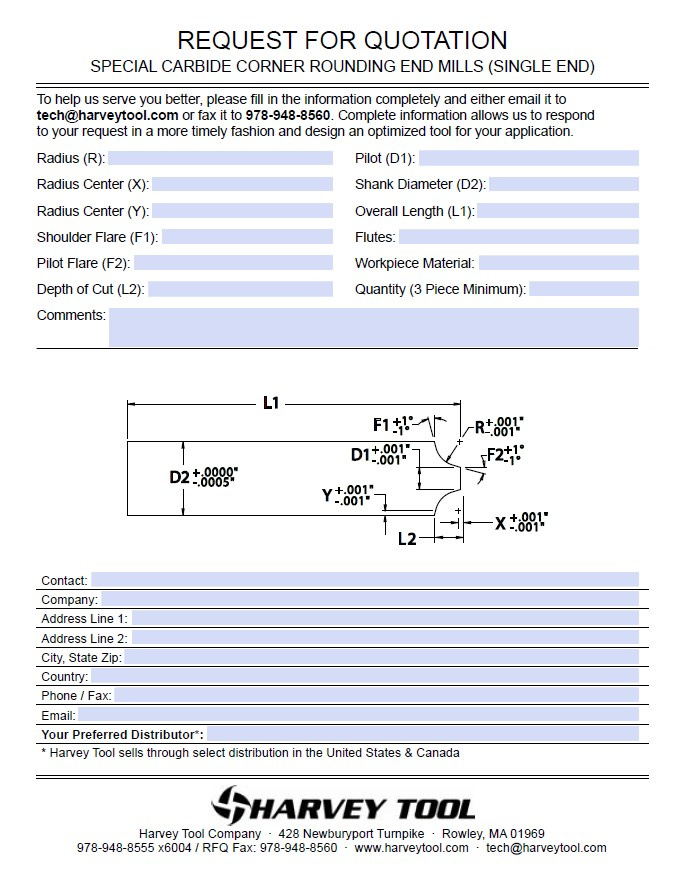

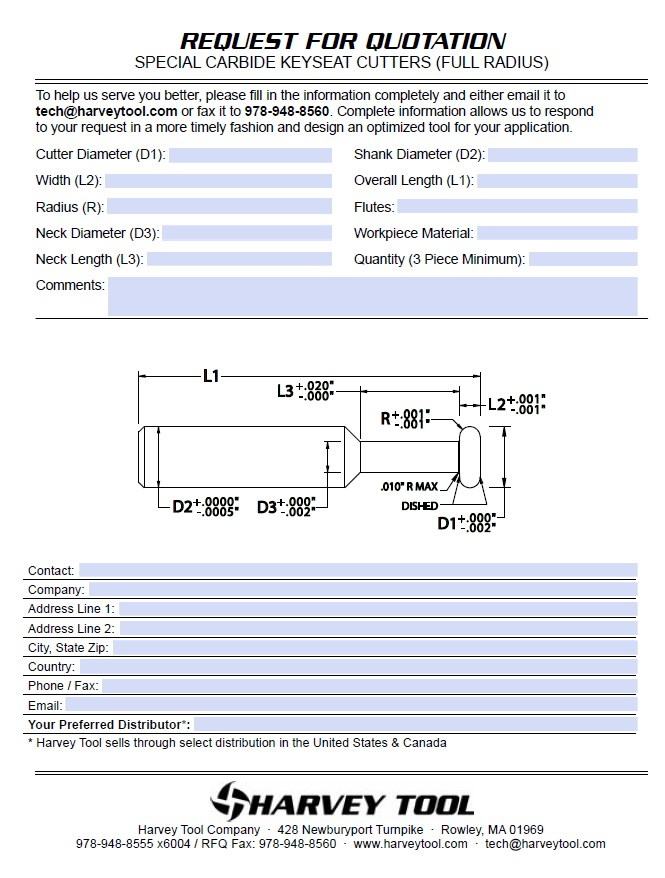

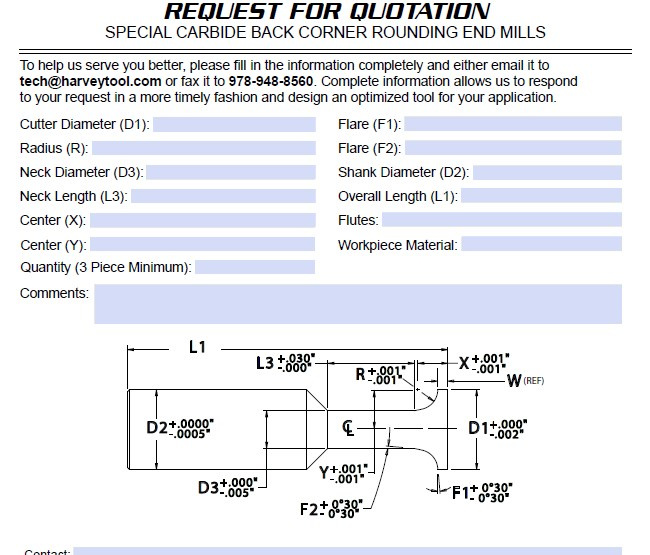

If you are making more than a few, you might consider having a tool ground to shape. It looks like you would need about a 1" shank tool for part shown.,

Thank you for the response. Please note that the tool you recommended is for a curvature in the opposite direction. I don’t believe it would work for this application.

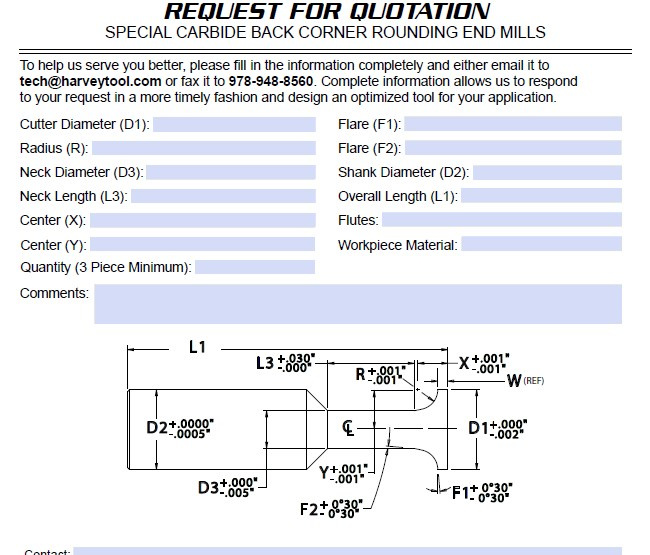

If they can make a back corner radius tool, I bet they can make a tool to machine your form

1 Like

That is definitely a possible route to take. I will contact them and see what they can make.

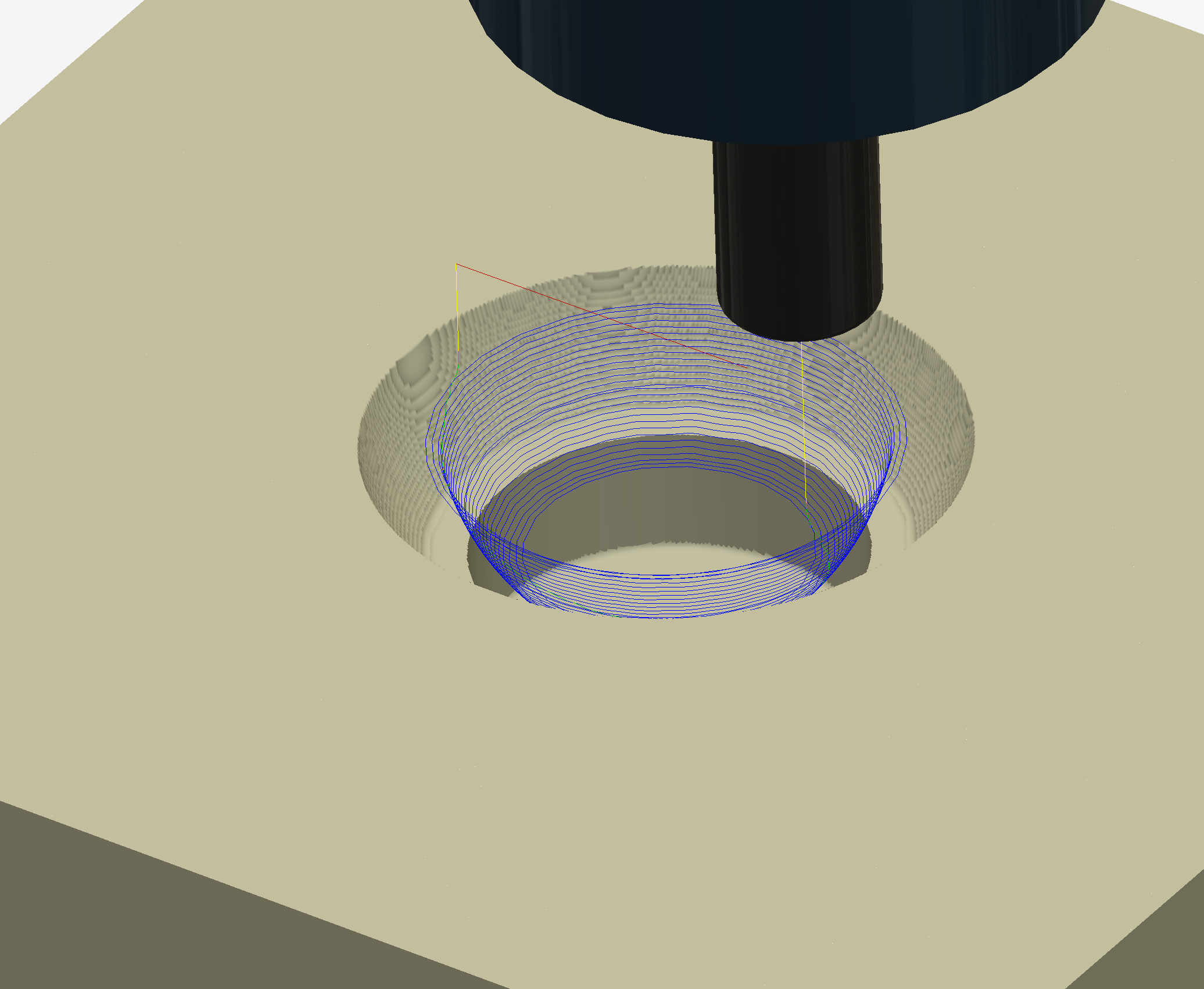

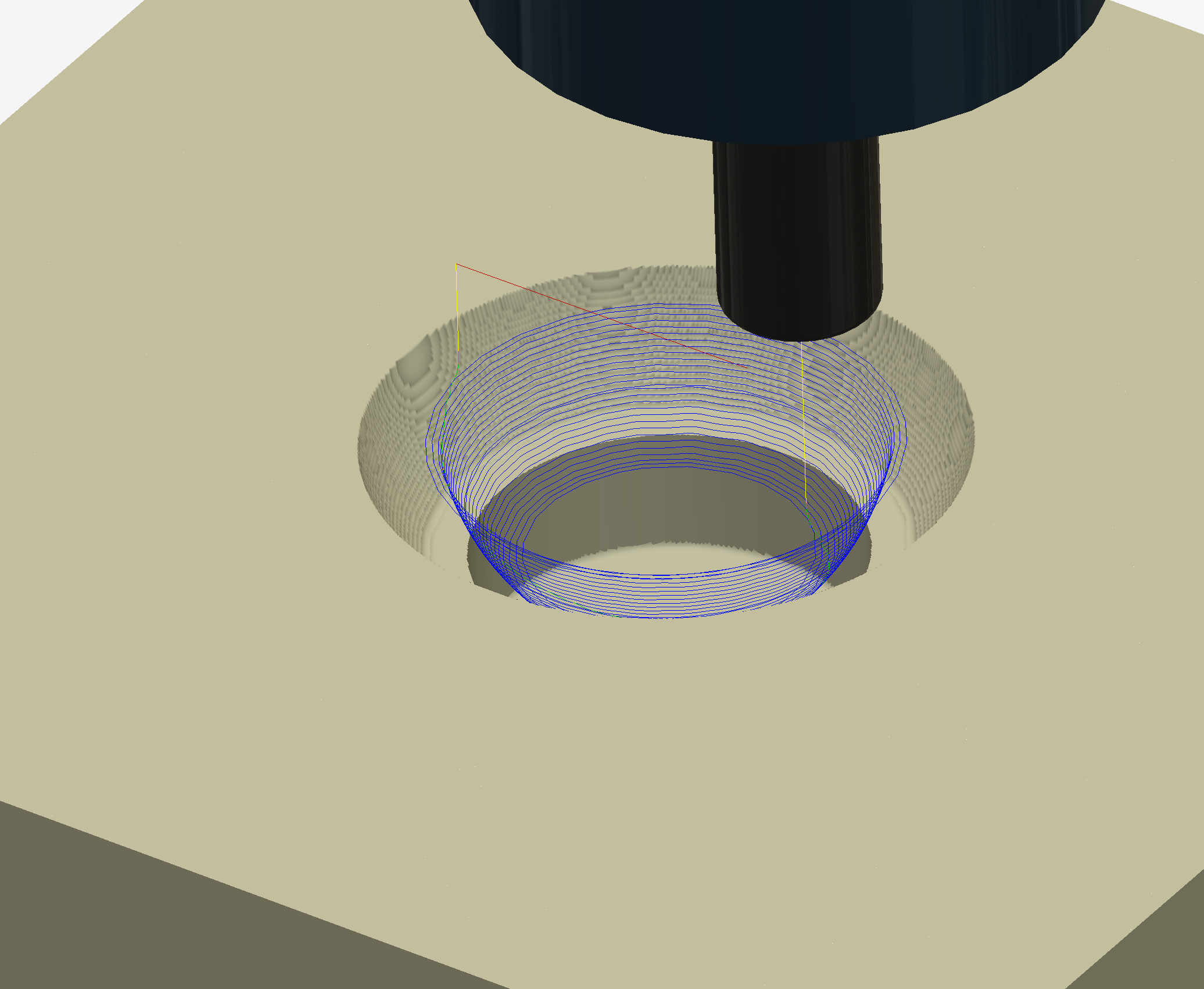

Flow or Scallop with a small ball mill this is 3d tool path that could be an option as well.

I am having a hard time downloading your file to add a sample tool path.

1 Like

Sorry about that. I am not at my computer at the moment. I will try uploading again when I am. Thanks .

1 Like

Its all good.

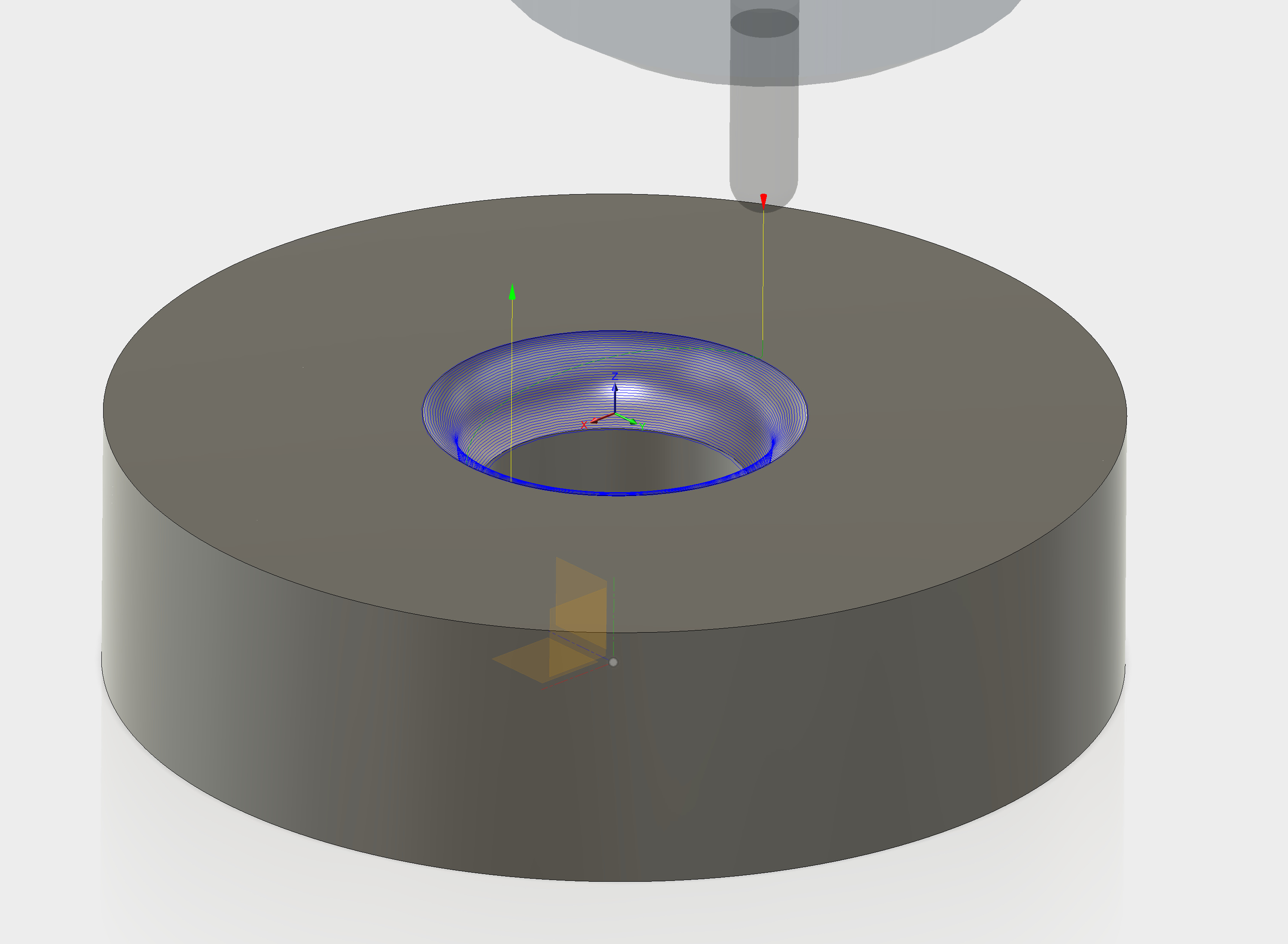

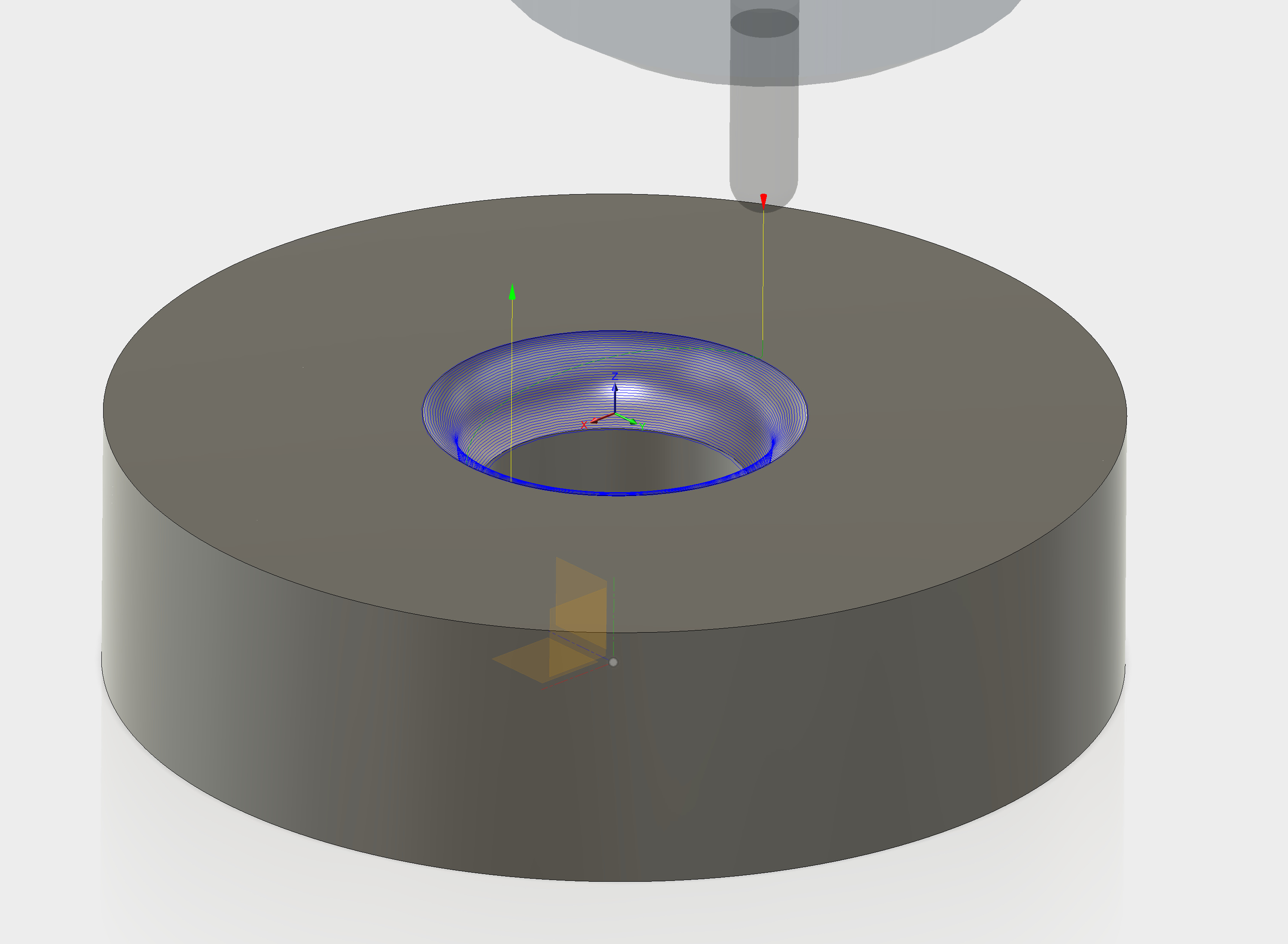

I made my own model just off of what it looked like. this is the scallop tool path I think it would work the best out of the 2 options I mentioned. I guess the problem would be the sharp corner at the bottom of the arc

1 Like

I was expecting to have to use a different tool for the bottom corner. I’ll try the scallop when I get a chance to see if it cleans up with only 3 axis.

@DerekBahner I am more of an old school machinist. We are talking about a weld groove right?

take a peace of 3/4" CRS 1018, 8620 mill a slot in the end and braze an old insert in it not a coated one. Hand grind the parcel ark you need then bang them out.

I see it taking a square shoulder tool, to use a 3d tool path because of the tangent of the ark and flat.

Just an other view point.

2 Likes

The square shoulder eliminated a single tool application using CAM to create the radius and shoulder. I am an old school machinist also, I would have created a single flute formed endmill, probably hand ground the radius, then added the flat face at bottom of radius. I carried in my toolbox a dozen or so blank HSS single flute blanks of various diameters. They came in handy when you were working injection molds and you were machining a form and it’s draft.

Thanks all so far for the ideas.

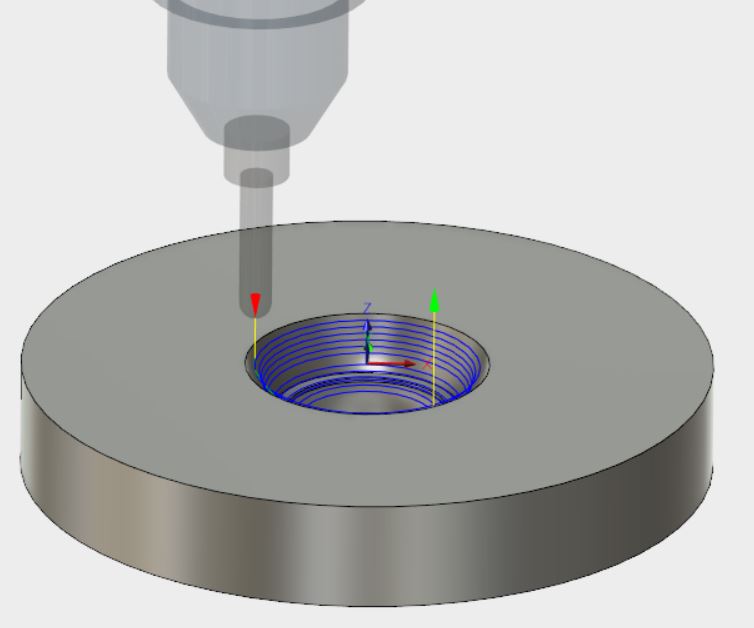

@Billy-Boyce I tried the scallop (see screenshot below). It still seems to want to make the same circular tool paths as with other strategies (which will take forever to clean up) instead of what was shown in your screenshot. Are you using more than 3 axis for yours? Or is there something I should change in the programming? Thanks.

1 Like

The pic I posted was the same thing it just has a lot more times around and yes no 5-axis required. If you wish to go this route maybe a bull nose would be better. Then you could also cut the shelf. If its just a weld grove the fillet at the bottom of the shelf could be cleared with a bevel on the pipe.

Here try this https://a360.co/2LilkNq has the tool path sample on your part.

1 Like

Thanks Billy. It’s hard to see exactly how it will clean up. Will have to run a few parts to see for sure.

2 Likes