Hello,

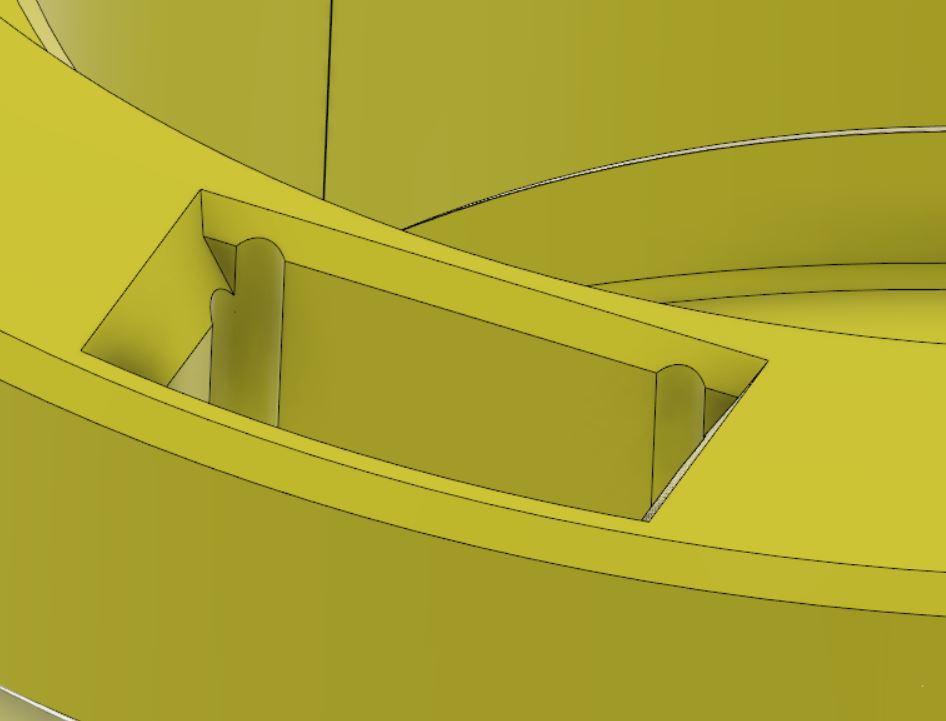

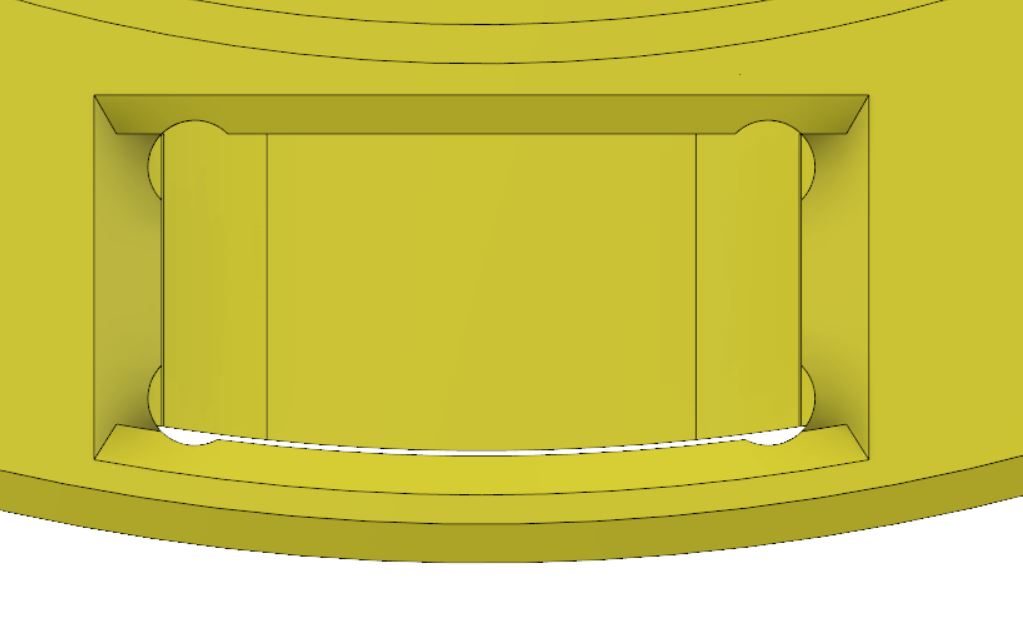

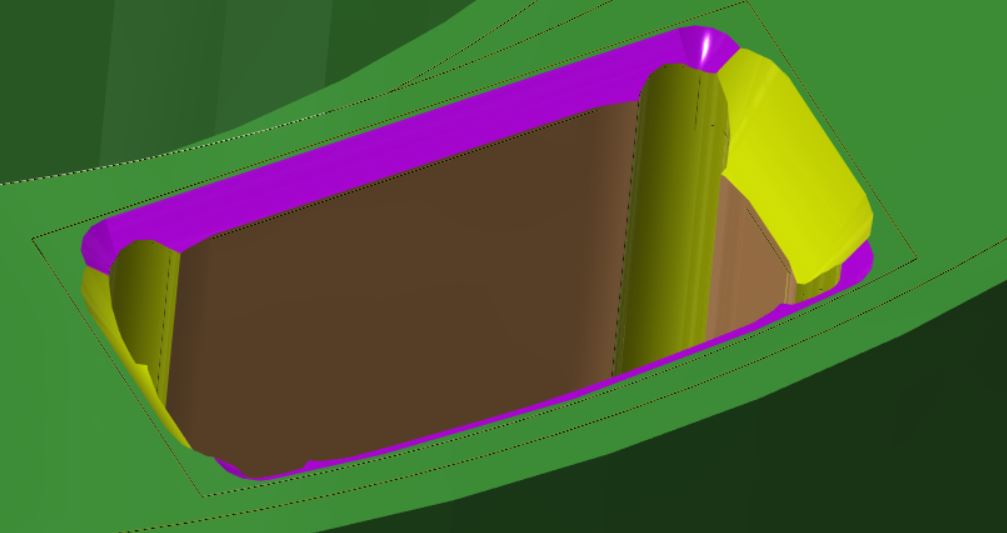

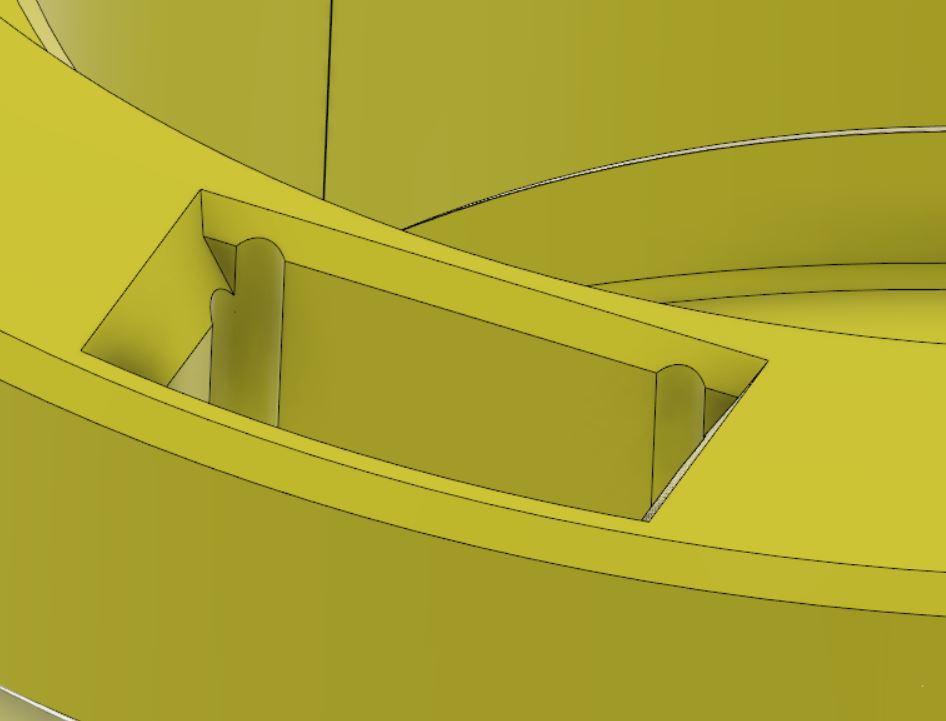

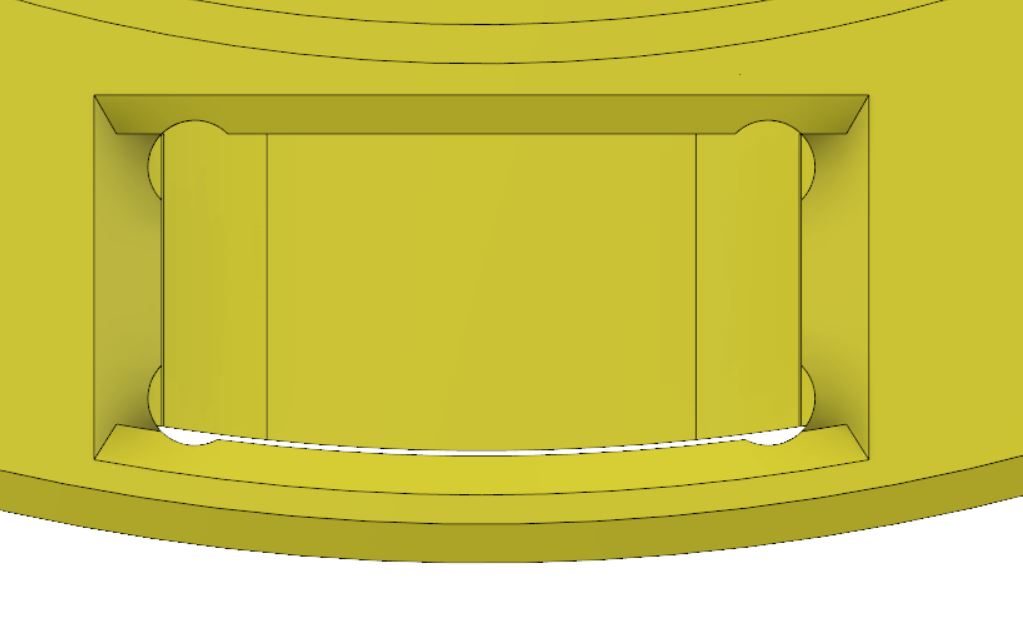

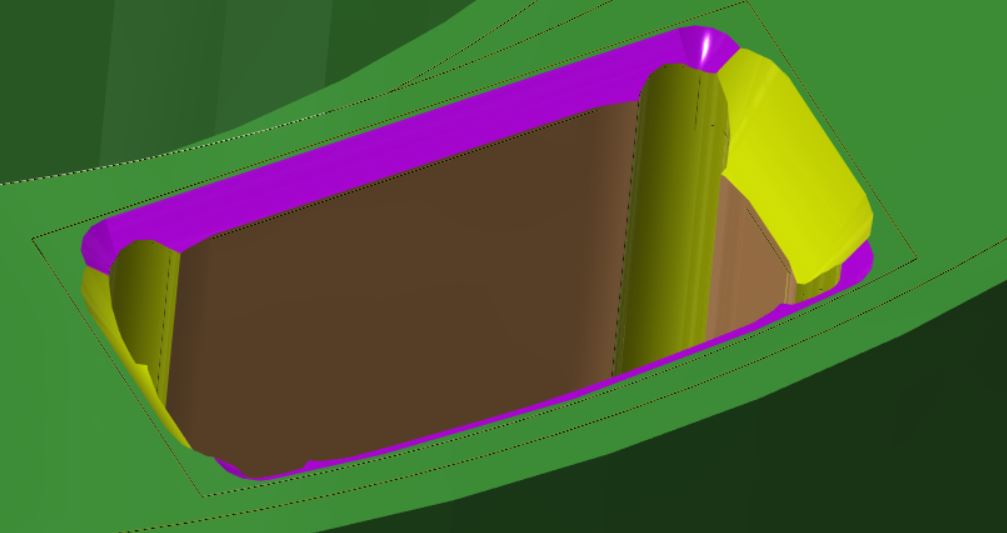

Does anyone have advice for the best milling strategy to use for the internal pocket edge chamfers in the pictures below for Fusion 360? The pocket size is .146" x .323". I already have the main pocket roughed and finished, including pre-drilling the holes in the 4 corners. The long edge chamfers are .02" x 45deg. The short edge chamfers are .060" x 30deg. I also roughed out the chamfers with 90 & 60 deg. chamfer mills (see simulated picture). I just am not sure how to approach finishing the chamfers on the top edges efficiently. I only have 3 axis to work with. Tools available are small ball end mills (1/16" & 3/64"). At first glance I am thinking 2D contour. Thanks in advance!!

1 Like

If you have to get the sharp corner you would probably either have to tip it or 3d it will a small ball mill.

1 Like

A round tool can never make a sharp corner. Unless you can run an end mill on a slant (ramp) you really cant get that done with 2.5 axis toolpaths

1 Like

If you can figure out what is the biggest radius you can get away with in those corners. What i did on something very similar was drop down and use a 0.02" ball nose. It was a tight fitment for holding a part that was having to hold very tight locations for pins to be pressed into it. Surprisingly, worked great and i ran it pretty fast yes it will add to your cycle time. Yet this will be faster than tipping the part “IF” you can get away with a radius in there

2 Likes