Hello Forum,

I have several questions and I hope this is not to much for a single forum post.

When you are choosing your feeds and speeds, chip load and inches per minute on a particular tool do you start with the manufacturers data and the material you are working with? With the manufacturers info there will be a window of surface feet per minute high and low . How do you choose where to start in there? Some of it is trial and error Im guessing especially as I see some of the videos where the tools are being tested and run up to failure and then backed down. Do you have any other recommendations when programming a tool? Also do you ever exceed that window setup by the tool manufacturer? I have seen the videos where you run the facemill out to 800 inches per minute and the machine begins to lug down and then you back off. How do you recommend going from the manufacturers data to a test like the one in that video(pushing cnc machine speeds to the limit).

How to calculate the vise clamping force torque number. In some of the videos the operator is torquing down the parts to so many ft-lbs. How is that number calculated? Im guessing its a function of the part size and contact with the vise, cutters and operations to be preformed on it, feeds and speeds plus a safety margin. If so to some degree how is this calculated?

Mitee bite pitbulls and talons. I see them both used to hold down blocks of stock. Are the talons needed on the opposite of the side of the blocks with reference to the locations of the pitbulls or could a wall and corner be machined out of the fixture stock to hold the opposite side and only need the pitbulls and not need to use the talons? Or when it must not move under any loads both are necessary?

Do you ever employ tools like volumill to help with tool path creation to increase productivity?

Ok, the strategy for machining a part out of a block, the first side is done. You have machined a datum point on the front side to set the g54 reference point that you can get when you flip it over. You need to now machine some softjaws to actually hold the part with out leaving marks on it. How is this normally done? How do you determine how deep to hold the part, where on the part to grab, etc.

How critical is the tools shape. In that you have a standard endmill that is a specific diameter. But it is a ground chunk of metal. It will not be perfect. The diameter at the tip maybe off from the diameter at the top of the tool shank. Do we need to measure these tools or how do we account for these imperfections in tools when programming the toolpaths? Is there work that needs to be done on the tool before its put into use in terms of measurement? Like the touch off, is there a diameter setting that needs to be programmed to compensate for imperfect tools?

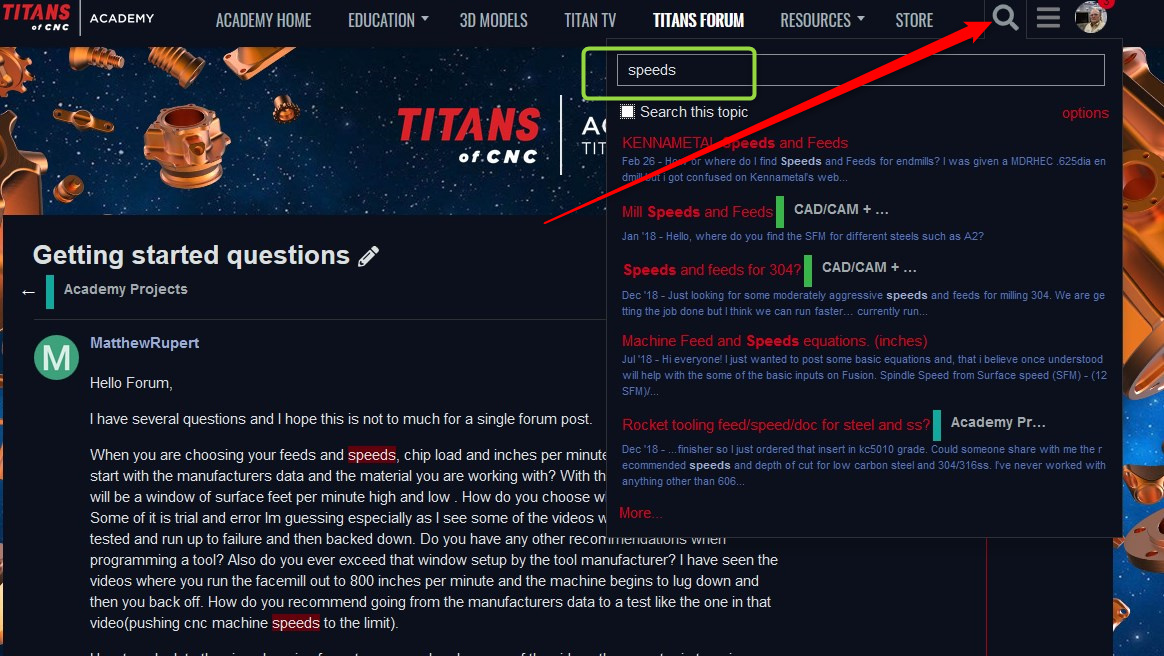

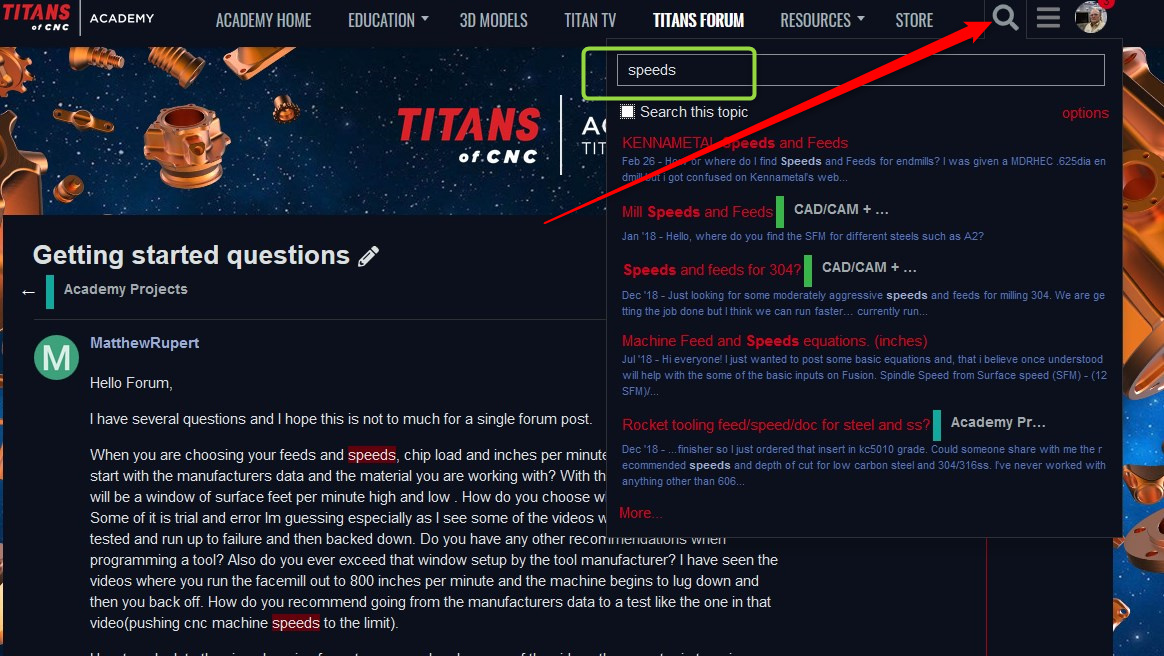

Final question is about the forum. Is the a mechanism to search the forum for questions so that I might be able to find an answer a question I might have without posting? That is if someone else has already asked a similar question?

Thank you for the help everyone.

Matt

1 Like

@MatthewRupert I feel you have too many questions in this one topic, most of questions have answers in the forum. Use the search function.

2 Likes

Check out the Titan CNC Fundamentals in the Education drop down list at top of page. It will answer most of your questions about torque. You can also check out Titan’s YouTube videos, he has a ton showing how it finds the optimum feed and speed of a tool and the material machined. The Art of Fixturing in the Education drop down has a lot of example using the Mitee-Bite components.

2 Likes

Thank you Stephen,

Ill look for the answers in the drop down on the torque. In one of the videos I saw I recall the operator calling out the torque to use, but I imagine there is a fairly complex equation to determine the pulling force and pushing forces a tool will exert on a chunk of material as a function of amount of engagement of the tool into the material, rpm, and chip load. Hopefully there is a general rule of thumb that can be used as I think this could get very complicated. It would be interesting if the cam tools could actually look at the worst case loading a part would see and then provide that as a setup parameter. Maybe this is already done?

Ill look around for the other questions and repost if Im still wondering about some of the stuff.

Thanks for the help Stephen!

Matt

1 Like

https://youtu.be/Zg1bbez8XyE

A standard vise is stronger than you think. It doesn’t take much pressure to hold something. Take in how hard your gonna machine the given part. Plus how heavy of a cut you want to take. Then think about all the parts you have done with a Torque Wrench in a vise tighten by hand.

Best thing to do is take a piece of scrap and setup it up I would tighten by hand then test the TQ on it. Then try applying that same amount of TQ with the Torque Wrench. Put some gloves on and try to rip it out of the vise. Lastly i would try different depths of cut with different step overs. just to see how rigid the part really is and what it can take. Also, look at you part make sure the jaws didn’t mark the part.

This is all an educated guess on Vise TQ you would hate to see the math involved in this plus all the variables. I have an Intern Engineer maybe I will give him this as a project and set out a data table. Could be his Senior Project I think 1.5 years of data might make it somewhat reliable data points

1 Like

A ton of variables would be involved, not sure if it would be feasible, if so, it would be already be available.

- Material density

- Material thickness

- Clamping surface (sq.in.)

- Clamping surface finish (smooth, serrated, etc.)

- Parallelism of clamping surfaces

- Size of clamp screw, type of screw thread, clamp screw material, nut material

- Height of clamping surface to screw axis,

- Cantilever variables, and on, and on, and on, etc…

2 Likes

Oh the variables alone would drive a man insane defiantly.

1 Like

I believe one of the key factors of using a torque wrench for clamping purposes would be for consistency on closed tolerance parts. So whatever torque setting you come up with using a torque wrench helps you ensure the vice is tightened the same reading consistently. There’s my half a cents worth LOL.

1 Like

@Rumpelstiltskin, way to keep it simple. you want to clamp hard enough it does not come out during machining and not too hard that it will damage part or vise.

2 Likes

Thank you all.

So from a simplistic perspective, for theses first parts where there is a torque number specified, Ill just use those as a general reference and see how it feels. My main motivation for asking this is a few years back I was facing a block of aluminum and my facemill pulled the part out of the vise in a instant. I dont ever want to do that again. So that being what it is Im trying to learn from you what would be a good way to prevent that from ever happening again. So crank it down as light as possible to not screw up mar parts or have them reshape and be out of spec, but tight enough to make sure the part is in the same place before and after the operations. To your points Mike and Stephen, the number of variables in this equation makes this a challenging answer to calculate and I do see and appreciate that. Part of the reason I was wondering if the cam software could not solve this for us or maybe already does as it should know the details of tool engagement, speeds and feeds, material hardness, etc. The vise details could be added. Anyway hope you guys have a great weekend! Thank you for your responses.

1 Like

A lot to grasp in one question. As far as speeds and feeds, I usually start in the middle, the average of the mfgrs numbers. Then adjust from there.

1 Like

@MatthewRupert, I get it, slinging a part out of the vise is a nightmare, In an attempt to answer some of your questions… The CAM software(s) I have worked with will not calculate the amount of torque to tighten a part, maybe you can use Solidworks and develop a simulation that could calculate that (above most machinist pay scale). So in the past, pre-torque wrenches to tighten things down, I used my body weight and had great success of not having parts jerk out… My process I call the 3 o’clock;9 o’clock clamp/unclamp method. When I tighten the vise using the vise handle and it snugs up, I then remove vise handle and then align the handle to the 3 o’clock position, I place back on vise nut and then with both hands on end of vise handle I straighten my arms and position so I can push straight down using nothing but my body weight. When I am ready to unclamp the part, I place the vise handle at the 9 o’clock position and again using nothing more than my body weight unclamp the part. I have gotten great consistency using this method the past 30 years.