Hi, I am not sure what tools are available for making 1inch thread in a 1 inch deep hole, thread and drill? In mill with bt40, or cat40. 1unc 8,

I would use a thread mill, either single point cutter or a tap style cutter.

Kennametal 5416962, found this, now what holder would you use?

I would not use a tap for that hole. Requires too much power.

I would use a thread mill.

Like this

https://www.mscdirect.com/product/details/81262487?fromRR=Y

Or like this

https://www.mscdirect.com/product/details/76418292

i have lots of power…

In that case, I would use a tap holder that fits the tap. Something like this https://www.toolmex.com/itemdetail/8-145-5010

That particular one is too small, but they come in different sizes.

Found this 5593181 Kennametal, but not sure how to program it…or even

https://www.mscdirect.com/product/details/76418292...from above…

https://www.mscdirect.com/product/details/76418292

so how many holes can I do with this one? @JimDawson

Most likely hundreds of holes if everything is working correctly, depending on the material you’re working with. You normally use your CAM program to generate the G code. You should have an option for thread milling.

Hello,

Here are some additional multi-form cutters including indexable tooling which can be more flexible.

https://www.mscdirect.com/product/details/66297102

https://www.mscdirect.com/product/details/53375572

https://www.mscdirect.com/product/details/75405910

https://www.mscdirect.com/product/details/47497326

Allied Machine & Engineering has an excellent technical guide on Thread Milling available online.

LD

Threadmill - it’s fast and easy on your machine. Plus you probably already have an tool holder on hand.

If you do not want to invest in the thread millling tool, you can use a a lathe boring bar with the thread milling cycle (with thread form shaped single point bit).

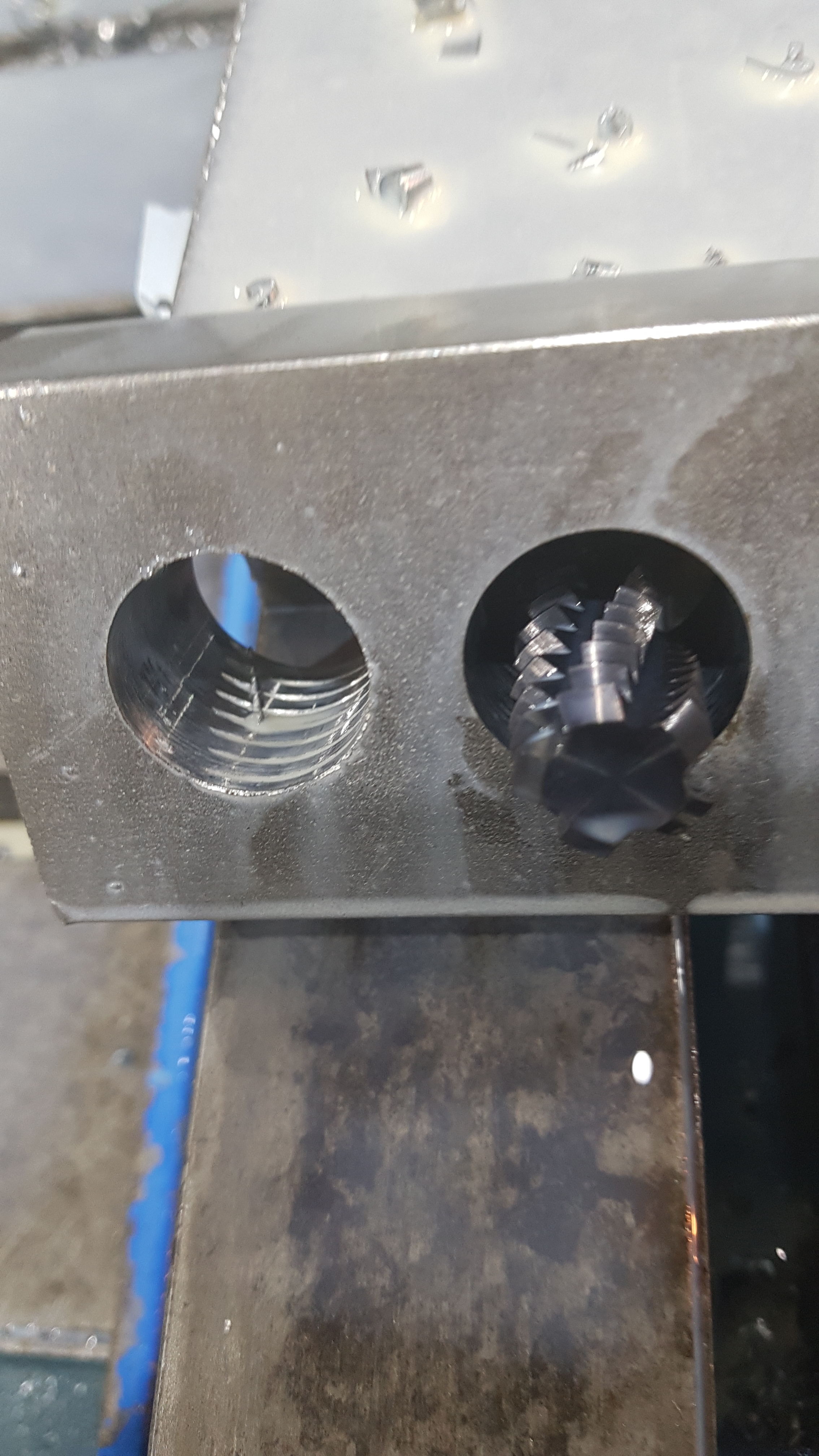

WHAT HAPPENED, Used a col-let holder for the Morse 1-8 thread mill…and broke, did not even make a single thread…

O1001 (HOLES5)

(T18 D=0.625 CR=0. - ZMIN=-1.1 - THREAD MILL)

N10 G90 G94 G17

N15 G20

N20 G28 G91 Z0.

N25 G90

(THREAD4)

N30 M09

N35 T18 M06

N40 S1500 M03

N45 G54

N50 M08

N60 G00 X0.8952 Y-0.0625

N65 G43 Z0.64 H18

N70 G00 Z-1.02

N75 G01 Z-1.0375 F39.4

N80 G18 G02 X0.9578 Z-1.1 I0.0625

N85 G01 X0.989

N90 G17 G03 X1.0515 Y0. J0.0625

N95 X0.6985 Z-1.0375 I-0.1765 F13.7

N100 X1.0515 Z-0.975 I0.1765

N105 X0.989 Y0.0625 I-0.0625 F39.4

N110 G01 X0.9578

N115 G18 G03 X0.8952 Z-0.9125 K0.0625

N120 G00 Z0.64

N125 G17

N130 M09

N135 G28 G91 Z0.

N140 G28 X0. Y0.

N145 M30

%

Hello,

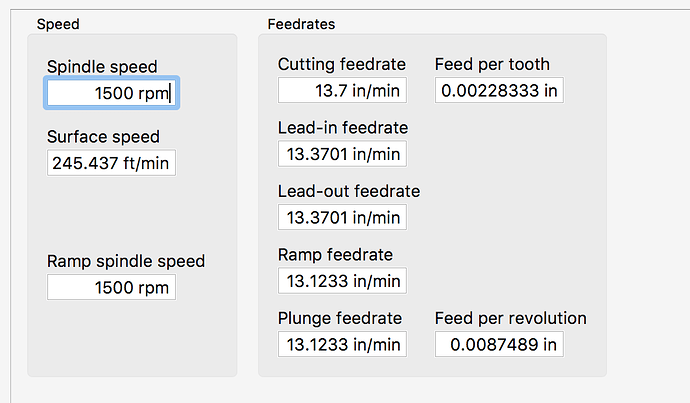

You’re running at 39.4. You should have it running at 13.7.

LD

forgot how to share a file…? need to fix this…help

I would like to share the file to fix this…I’m very green at this…so that is the only issue , lead in and out feed rate?https://a360.co/3biZHtd. ok, here is file…

so this is running on an old milling machine with just low pressure flush… what do you think about the rpm…? Is it ok to use a collet er20 to hold this Morse threading tool…? THANK YOU…

HI, I have been using “stock to leave” to slowly increase the thread size, is that the correct way to do it?

So if this thread is to small, use a negative stock to leave…?

Yes, that is the way I make minor adjustments to hole sizes.

hi, I am now using this tool

https://www.iscar.com/Ecatalog/Item.aspx?cat=5603885&fnum=1650&mapp=TH&GFSTYP=M&srch=1

running at 1200 rpm and feed at 2 inches per min…(I can set at Machine,) anything faster it sounds rough…this seems slow to me?. Also using wear as an offset adjustment at machine to adjust size of

thread, this works nice…

The feed does seem slow, but if the tool and the machine sound happy, then I think it’s OK. You are removing a lot of material with that tool.