I’m working on a new setup for some parts at work and looking for some ideas / best practices / etc.

We use Inventor with HSM but I also use Fusion 360 at home.

The parts will be on a HAAS VF series with a HRT210 indexer / 4th axis. with both “pre-NGC” & NGC controls depending on the machine that is open at the time.

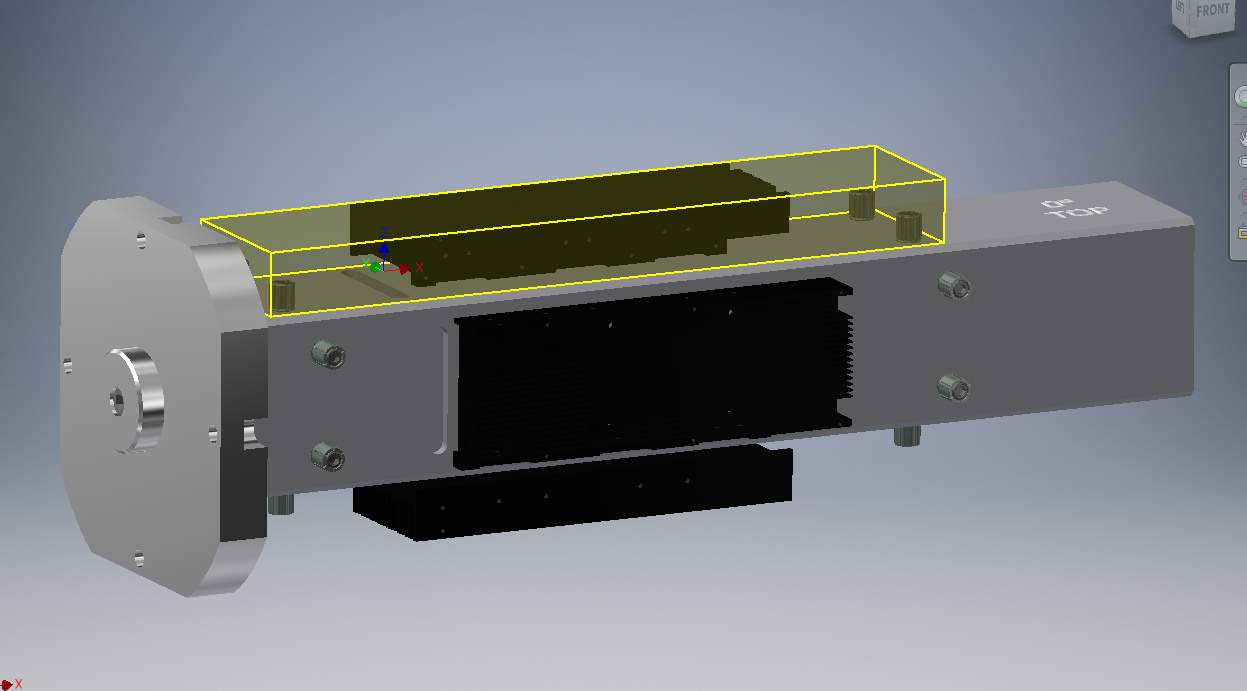

There will be 1 part on each side of a 4 sided “tombstone” that will get 3 sides finished ea. (5 sides if you include finishing the ends side cutting with an end mill)

Will it be better / easier to program with 4 different WCS’s, or use my model / assy as one “part” and program to that?

Second question… What would be the best place / places to locate the WCS’s?

I’d like to set each part with it’s own WCS but I’m not sure “where” to set it… should I set it to the rotation centerline & an X-axis location, or will the HAAS DWO-TCPC take care of that for me if I set the WCS at the model WCS or any position of my choice??

Give me all your ideas / advise, I’m looking for options and clarity on this since all I’ve been finding on youtube has been 4 & 5 axis with one part mounted instead of multiples, or it’s multiples but only on the face & no side work. I’ve run 4th & 5th axis before but it’s always been on a single part… I may be overthinking this???

Thanks!!