I searched around a bit and only found tid bits of information. So my question is would you guys add some parts that just use a 4th axis and not a 5th. I know simultaneous 4th isn’t there yet but even just some tips and tricks would be great. I have found very little info on 4 axis stuff. seems everyone just jumps to 5. But would be cool to see how to set up and use a trunion as well as best vise to use and setup procedures. Or if anyone has links to good information that would be great too!

I agree.

It would be great if someone could take a little bit of time to show to all of us about 4 axis.

Not having just a 4th axis system, but using the 5-axis programming, I believe you could use same, but check off any process that has a 5 axis path for machining… Just make sure you wrap you head around the planes of your indexer/tombstone/pallet locations, Example G54 equals 0 degrees, G55 equals 90 degrees, G56 equals 180 degrees and G57 equals 270 degrees. You still run your CAM process by selecting the Z axis/X axis of each fixture side. Code should work. I think I could make it work, even if I have to use the Manual NC functions in Fusion 360

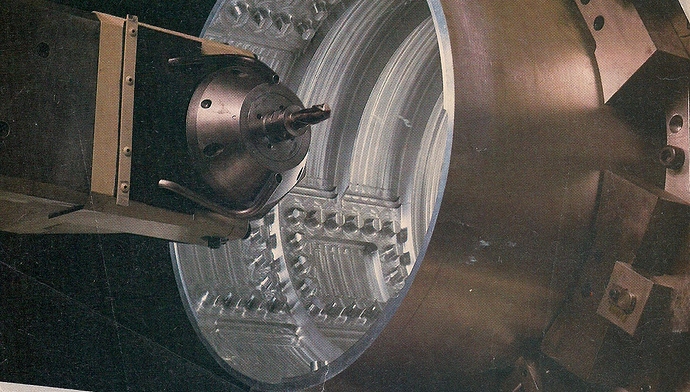

Hi Everyone, I programmed an Onsrud 4axis for a part on the DC-10 original first ships, Yeah somewhere early 70’s. Think this way, the rotary axis designations are A, B, and C. A rotates “about” the Xaxis in the YZ plane. B rotates “about”: the Y axis. We did this with blueprints and punched cards. Graphics as you now know was not invented yet. Here is a picture of 4axis

It depends on if it is continuous or 3 plus 1 and what the machine can do like dynamic offsets.

This part I would use just one work coordinate with Y and Z on center line.

Some you could build like a 4 sided fixture with 4 parts

a horizontal mill is really a 4 Axis machine because just about everyone uses a Tombstone

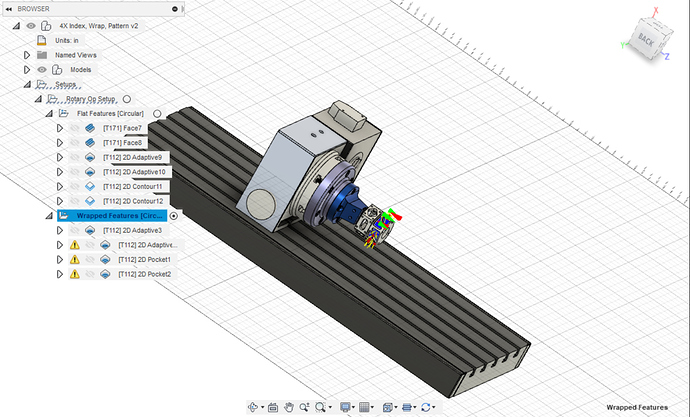

I made a copy of that 4th axis pattern - here is a share link file - we are trying to build our own workholding similar to the raptor but using Mitee Bite clamps

I forgot all about the samples included in Fusion 360

I learned a whole bunch from that example - my student made a shifter knob 3d machining on our 4th axis using Fusion - pretty impressive