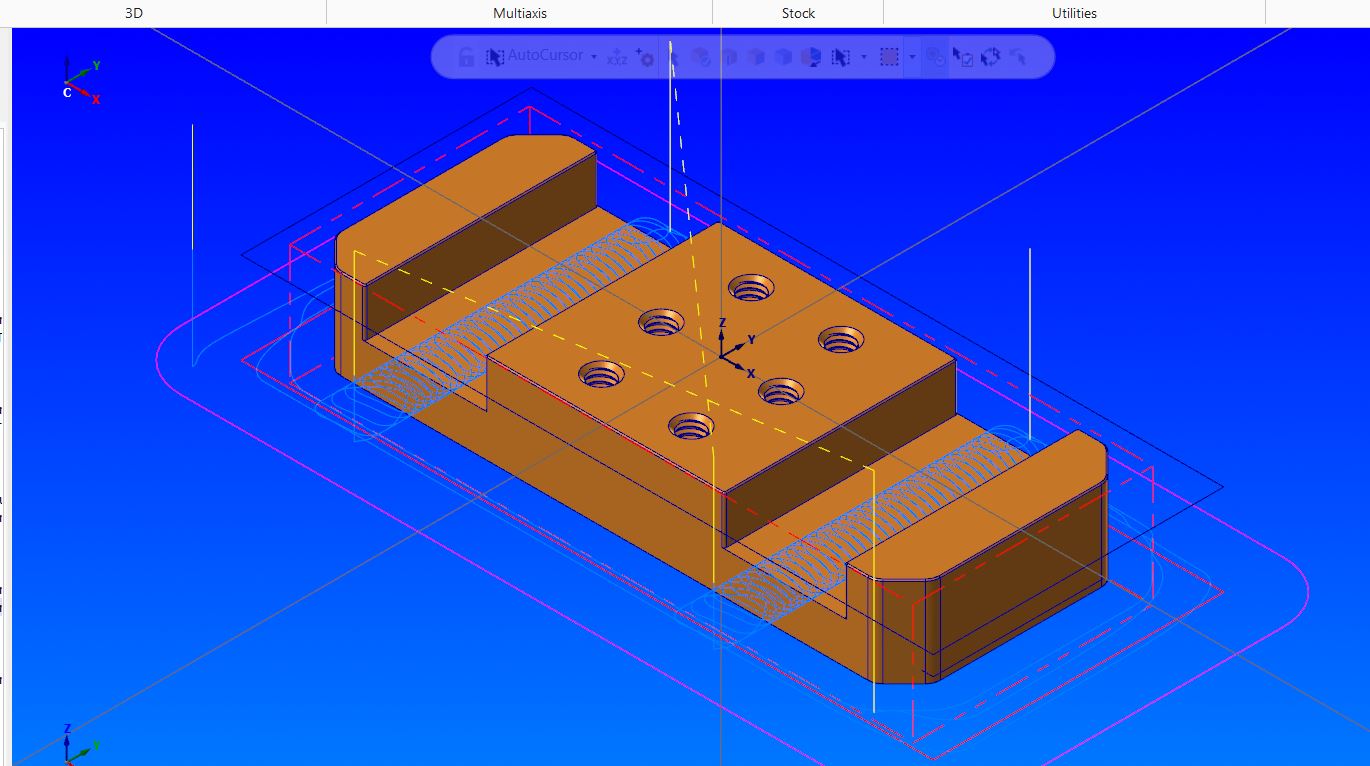

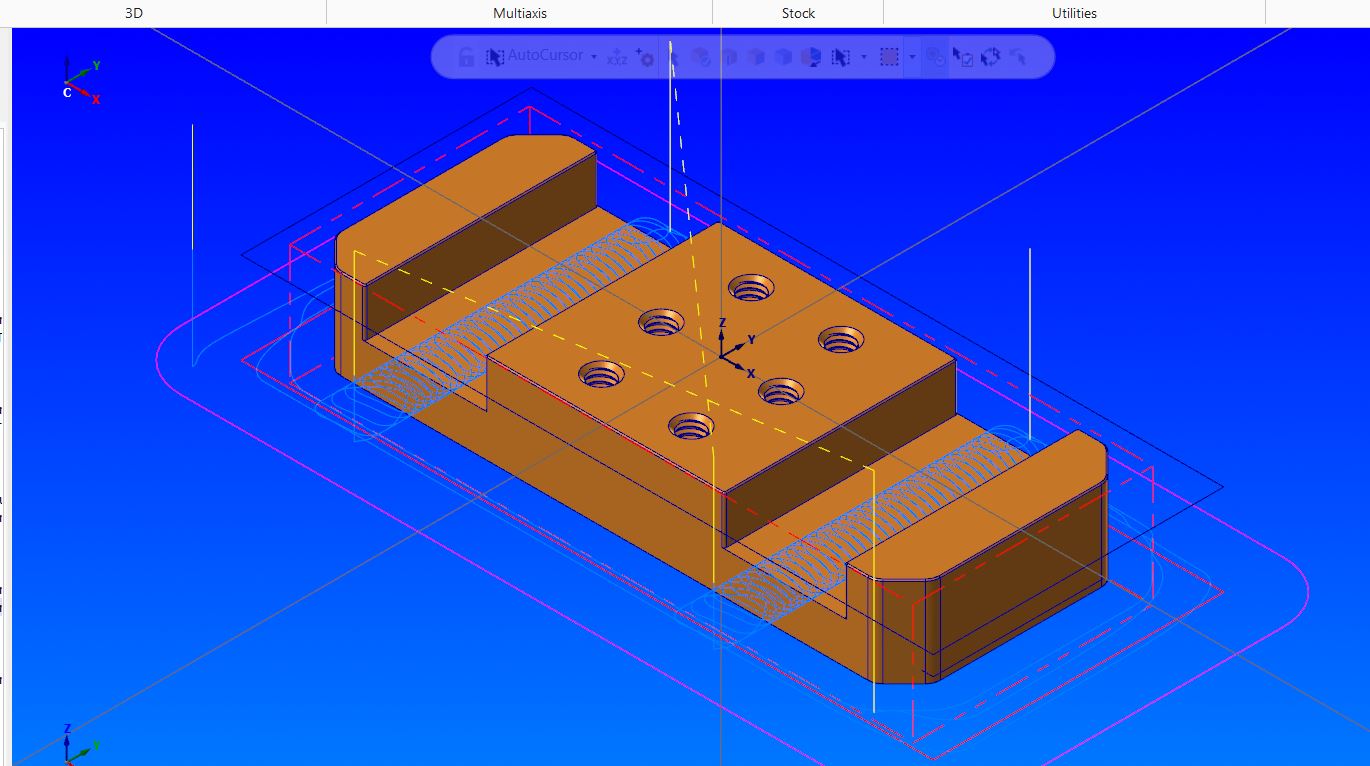

I was on FB and was inquiring what is the equivalent of 2d Adaptive roughing in MasterCam or others.

Something simple that doesn’t require as many key strokes - there is not from what I tried. I got suggestions - but just about all required 3x the amount of work - We were finally able to use a 3d Opti rough in a 2d scenario but you had to have all settings correct - - we used 2d dynamic milling but needed at least 2 selections - draw a containment ( for stock - it doesn’t identify stock) and many selections.

2 Likes

A good programmer can use anything out there. Fusion 360 has been a great asset for me. It is very intuitive, the CAD and CAM are interactive, there are great libraries of video tutorials., it is affordable. I liked it when it was HSMWorks (still use in in my Solidworks), and like it still.

2 Likes

To each his own to be honest. I have both MasterCam and Inventor using them for Machining, and wire machine. I have used MasterCam since I got into this trade 10 years ago, and only been using Autodesk products for 1.5 to 2 years now. I can sit down and completely draw, 3d model, and write a program on Inventor faster than any other CAD/CAM software I have every used. Then again I know guys that won’t take the time or try and learn it, and rather run MasterCam, SurfCam, Gibbs, and so on. I took a job never even knowing what Fusion or Inventor was, and I learned them both in a week on youtube. Very easy and very powerful software hands down. Can’t like every inch of something just like music I love Motley Crue but I don’t lover everything about Vince Neil or every song.

4 Likes

on the job I don’t get to choose the software - so we all make it work. Its easier to learn another software if you already know one. I was just fascinated by 2d adaptive and thought - how do the other companies do it. I was able to eventually get good process in Mastercam with 2 different methods. If I plan on teaching Mastercam after they learn Fusion I wanted to show how to do it that aligned with what they already knew. Mastercam does have some more power with selections but I also think thats where it becomes harder to learn - Like its a secret how to use it well.

1 Like

Even after completing MasterCam University, I would spend lots of time figuring out how to do surfacing and special contouring. Yes, you can do it, but you are right, you might need that secret handshake before you can step up to the next level.

1 Like

I agree with the secret hand shake lol. I spent lots of time trying to figure things out or manipulating it to work to get a job done. I just wasn’t a huge fan of MasterCam. I never got the choice till now and where we bought out another company is where the Inventor came. I just talked them into letting me keep it because what I can do with it. I still use MasterCam for wire machining.

1 Like

I think I was just beat up on FB Cad/Cam forum from this post - I see at last count 111 visits - so It must be an interesting discussion. I had a MasterCam user who is a fellow instructor from NC and we worked on how to use MasterCam in a similar way - then Al from Bobcad showed how they do it - Fusion was still the easiest by far. I did make a mistake and say that its was 2d adaptive when it was 3d adaptive

So I mentioned on my FB post in Cad/Cam that many of them are “power users” and some were offended. They said they spent a lot of time to learn all the techniques and that no excuse for people who just want the easy one click button. So when I mentioned secret society - that really ticked that bunch off.

Like you buy this expensive Cad/Cam software and YOU will need to figure out how to use it. I understand that the use and learning is dynamic - meaning that if you make changes that it may affect other changes and it can get pretty deep. I was only talking about entry level. and they don’t get it.

That it does need to be easy at entry level. That if we are all promoting trochoidal style roughing it should be easy to do 2 1/2 axis projects. Many shops out there are still unaware of new techniques as well.

2 Likes

I agree with your comment about some shops don’t know about new techniques. I have made a lot of tooling for John Deer assembly plant and my completion only has manual machines. I also farmed out some work to a nabering shop and they came over commenting about burning up tools. I told them it was there strategy taking several shallow cuts burnt up the end. when I told them to take full depth cuts with shallow stopover this was new to them.

1 Like