Hello guys I am new here I got some questions about I machining.

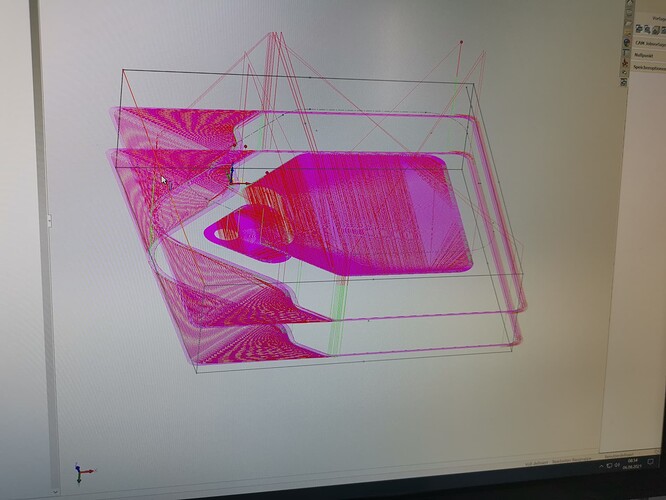

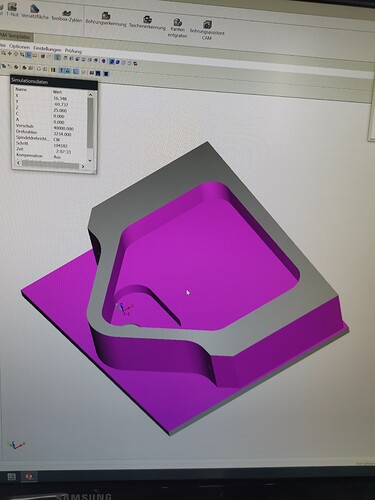

I am 23 years old I programming most of the time trying to get very optimized programs I got a new workpiece 1.4101 X14 I need to cut 52mm to get the block in shape 220x180x60 the finish part looking like a triangle and there are 2 pockets 22.5 mm and 33.5 mm deep so I need to cut much material i wanted to use a 16mm cutter but it take alot of time I use level 3 but i go up now to lvl8 but the time still looking not so well for my feeling and the other thing is the cutter should survive this any one got a good idear to make it faster (maybe other tools other job) or is someone here who know which tool and data I should use for this material I just got good experience in 1.4305 but I am still not happy with the tools.

Machine data

Dmu75 mono block

20.000rpm

Sk40

Tools

we use this one D12-16

Cooling oil/water

Sorry for my Englisch. I watching all videos and I love them and I trust In your knowledge.

Thanks alot