Good Day

I am looking to purchase the Kennametal Kit to start the building block series. I am a teacher and am new to CNC. I have a Tormach PCNC 1100. I am trying to find the correct arbor for the 3" face mill. Can someone help me out?

Thanks

Good Day

I am looking to purchase the Kennametal Kit to start the building block series. I am a teacher and am new to CNC. I have a Tormach PCNC 1100. I am trying to find the correct arbor for the 3" face mill. Can someone help me out?

Thanks

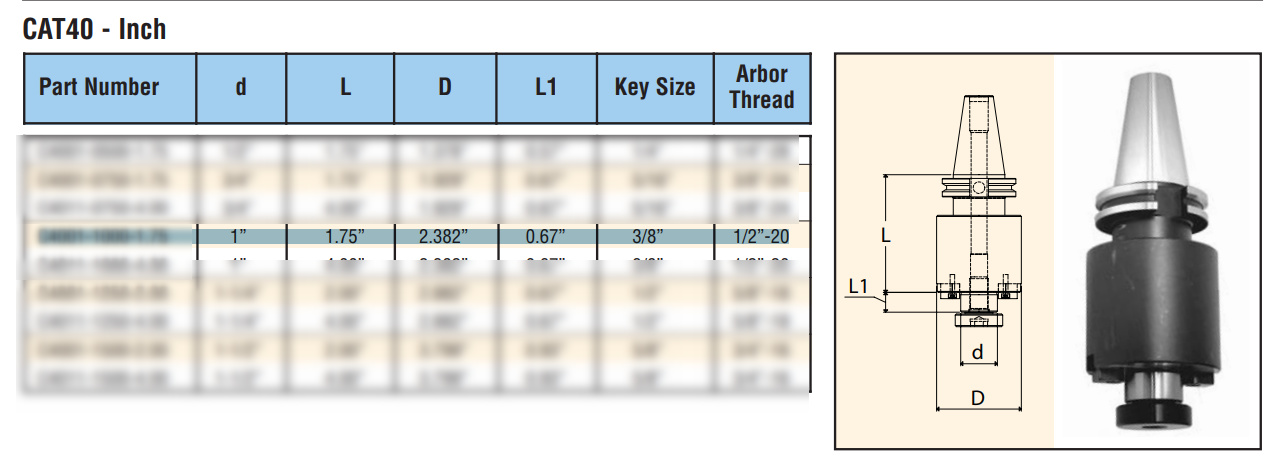

Arbor size is 1 inch

@GaryPotter

Looks like from what I see you have a R8 spindle you might want to verify that as a finding Ann Arbor with a 1-inch diameter Shank I’ll have to look into that a little more for you it’s probably not very common you may have to resort to eBay I’m by one from there. How old is some more looking and now I’m at work but I got some feedback that may help. TTFN

It is an R8 Spindle. Thanks for all the help @CoryLewis @Rumpelstiltskin

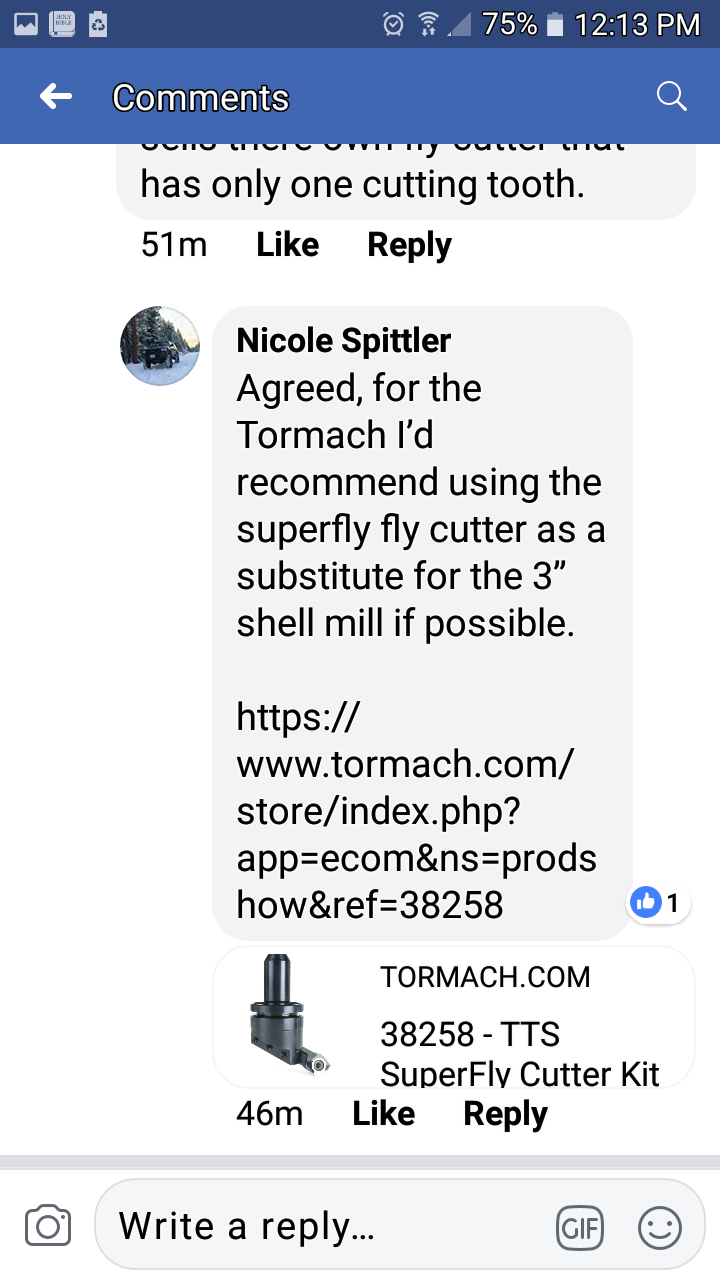

@GaryPotter it looks like there’s a little more information for you. That particular machine most likely cannot handle that size of a face mask that’s the chatter I’m getting from the post I made on the Facebook group. Here’s a couple of screenshots of how the post is going. You might reach out to Titan to see what he can do to help you. He’s a very approachable individual and he’s happy to help us out.

Hear is an Arbor on eBay. You can us the 3" face mill on your machine. BUT BE CAREFUL YOUR MILL HAS LOW HORSEPOWER SO YOU CAN NOT TAKE HEAVY CUTS

@GaryPotter lots of great information in this link.

At Grizzly industrial today they have an adaptor R8-1"

My old Bridgeport Series has a 3 phase 1 hp pancake motor running on a single phase VFD… It can turn a 3 inch face index-able mill no problem with modest cuts. Tormach 1100 has a 2 hp motor, I am sure it could handle it just fine…

All this needs to be taken with a grain of salt. Yes you can use at 3 in face male on that Bridgeport I have done it in the past. Speeds and feeds and depth of cut need to be in relationship with your horsepower. For instance with a 3in face mill you may only be able to take a .010 depth of cut with the feed rate of 10 inches a minute you will have to work that out yourself. My recommendation would be start with the light cut and work your way up. I’m not sure if the machine has a load meter or not but that’s what you could watch to determine how well it’s handling your cut.

Here is a Kennametal she’ll mill holder for R-8 taper. https://www.mscdirect.com/product/details/02910370