Hello all,

I’ve been working in and out of Tool & Die shops since I was 16; a LONG time ago. Most of my experience is with manual machines. Now I find myself being an engineer at a semiconductor manufacture and being the main guy setting up our HAAS Mini-Mill.

We’ve got a group of four guys setting up and running what most of you would call a prototype job shop. I’ve got many challenges ahead of me. The two largest challenges are learning G-code, CAD & CAM (lumped them together), and learning how to convince my boss, who has no machine shop experience at all, why the much more expensive 5thAxis vise is better than a four jaw chuck for our HRT160 Rotary. He’s a good guy. I just tend not to speak his language/terminology.

I’m the only one in the group with machining experience. So I need help justifying the cost difference.

I’ve not used one of these types of vise myself. Thus far, I’ve completely judged the 5thAxis vise based on what I’ve observed online.

Can you all put in your two cents? Is there a better choice than the 5thAxis or a four jaw chuck?

Most of our work will be ones & twos with the occasional run of a couple hundred of a certain part that works for us. We also have plans to expand our shop out to a full blown shop very soon. Right now we only have our Mini-mill and a laser.

Appreciate the help.

2 Likes

well with the 5th axis vise you have an opt of dovetailing but then it holds like no other. Plus gives you a ton of clearance for machining on 5 of 6 sides. I would lean more that way but really would be nice to have both on hand because you never know what will come through the door at any given time. I know how you feel trying to Tool up a department I’m doing the same in my situation also. I just got into Tool and Die after being in Job Shop for the last 10 years. Luckily so far it has been easy, when i first came in the Haas had nothing but HSS tooling. So i just made a big order for Carbide end mills and didn’t meet any resistance with my Plant manager he agreed. So growing is a pain but don’t give up show them why the company needs it and how much benefit it brings to the table.

4 Likes

Thanks Mike.

I agree with everything you’ve said. What I need help with is being able to articulate to my boss the benefits of the 5thaxis over a standard four jaw chuck.

He wants me to “show him how this one is better than the other” in a presentation basically. Since he’s not experienced with machining I need to, in print, explain how the vise I want is going to save us in the long run. Problem is, I’ve never actually used it so it’s difficult for me to explain to him WHY it’s better than just using a four jaw chuck.

2 Likes

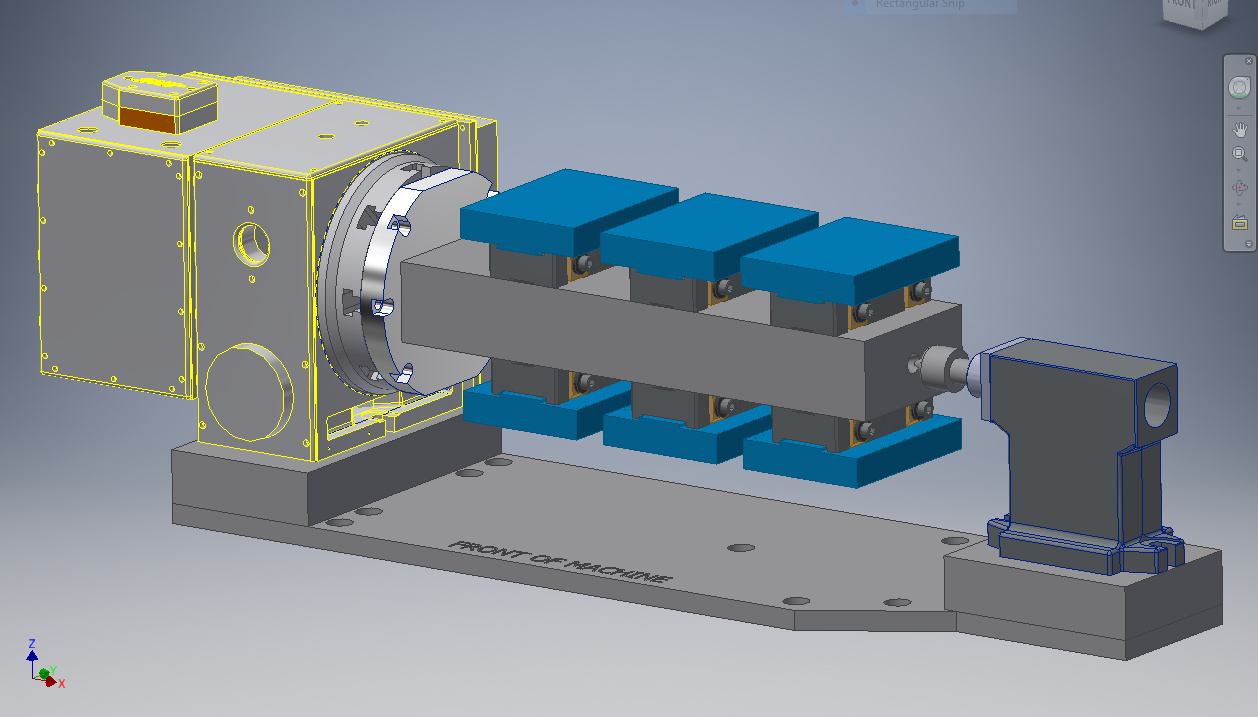

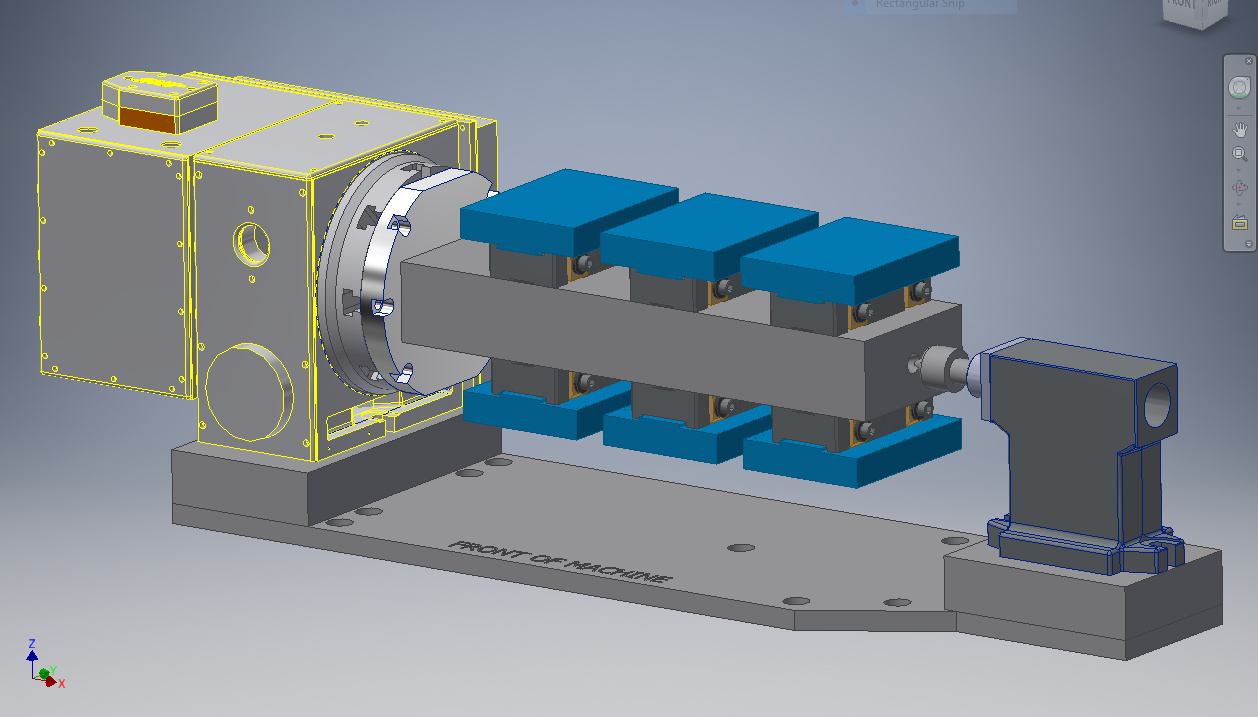

See if this helps any… There are 6 (six) D362 5th Axis dovetail blocks on this fixture, holding the material. This is on a HRT210 rotary, so just a couple inches bigger…

I can also take them off and use them on other fixtures, or as a clamping fixture if we get a “5th axis” on our machines. They have different sizes too depending on your work piece, but I’m guessing you’ve already looked into that.

3 Likes

This is what I would do exactly right here. find some Cad Designs like this and show your boss. You can’t get a better understanding than visual confirmation. Check GrabCad and other free sites for 3D Models download them or save picture. I think this would be the best way to get your boss on board with making change for the better of the company. I have used 3D Models and also wrote up a single page breakdown of how I see the Company growth going and what all it would open up capabilities wise for the Company. When you break it down and give them everything on a Platter so they can go to their Boss and take credit “IT Helps”.

3 Likes

Not sure if a Mini-Mill is best machine to try and do 5-axis work. It has very limited Z travel.

1 Like

We don’t have fifth axis abilities on our mini-mill.

I want to use the 5th Axis brand vise on our 4th Axis rotary. We’ve got a HRT160.

My counterparts are of the mind we should just stick a four jaw chuck on the platter and roll. I think that would be very limiting and setup intensive since every time you mount something on there you’d need to dial it in.

As Stephen pointed out, the mini-mill is limited on space. I don’t want to waste space with a big honk’n four jaw vise. Nor do I look fondly on spending time leaning in the tool to indicate things in all the time.

Mike. I’ll do some digging and put something together.

The other argument I’m fighting against is they feel the time/work it takes to cut the dovetails in every part is “just more work that’s not value added.” Deep breaths,…Deep breaths…

Thanks for the support.

1 Like

The HRT160 has a 5" centerline, the Mini Mill has 10" travel in Z. This will limit you if you have any tools that have any length at all. It would not take much time to have a 1st op that makes a dovetail in bottom of material, the benefits of superior clamping force will allow you to take faster cuts with less vibration and chatter. You could make you own dovetail clamp vise.

4 Likes

Stephen has a valid point a dovetail setup to a regular vise would give superior clamping force since you don’t have a lot of Z travel

3 Likes