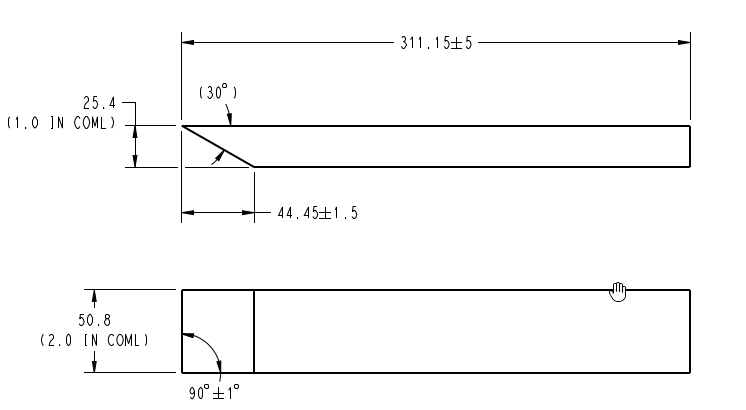

We have 10,000 of these bars to cut a bevel on. I have a couple mazak VTC300C vertical mills (3 axis) at my disposal for this project. Does anyone have recommendations on how we might setup vises or fixture plates to cut this bevel. Right now we are doing it in 1.3 minutes per part, and I’d like to see 20 or 30 of them in the machine at one time.

Is the material consistent in size (CRS). Mitee bites set on a pallet… You can load/unload from 1st fixture while machine is running the 2nd fixture. Weight may be a problem to easily remove from machine and mount back on pallet base.

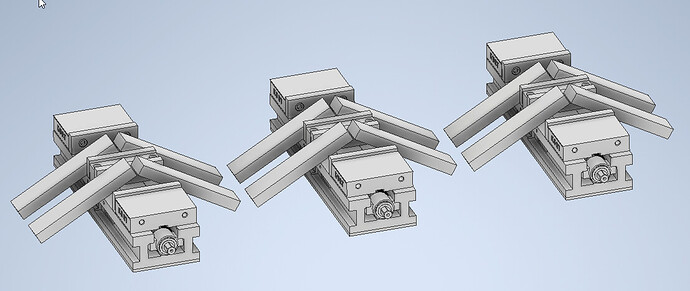

The material is laser cut from a much larger 1" plate, so the size is fairly consistent, however, the edge condition is fairly hard and a little rough (like a sawcut) from the laser cutting. They are about 5.5lbs per piece, so 10 would be 55# plus a fixture plate, so probably not a good solution, as it would likely weigh 80 lbs+ and get 10 at a time. I considered this idea, which would yield 12 parts at a time. We have 3 of these double vises. But I was thinking they might not get held tight enough. It would be easy enough to try one and see though. We get the plate on Wednesday so and have to turn out the first 800 in one week. #jobshoplife

Maybe use some Mitee bite uniforce clamps that will clamp two parts at same time (2x) if you setup for 10 parts, then you would need 10 clamps. Uniforce® Clamps | Mitee-Bite Products LLC.

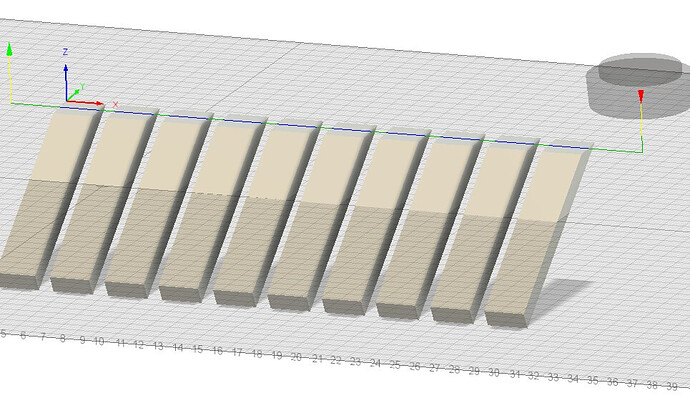

how about cutting the bevel along the entire plate, then laser slice & dice into pieces, with some quick manual deburring of the edges, if needed? No hard HAZ to cut thru.

Fixturing the entire plate can be easily done using a method explained by Brant Taylor in the March 2021 issue of www.ctemag.com , Machinist’s Corner.

If you still go with the double vises, drill soft jaw for a 1/4" dowel pin, to support the end of each part. I attached a pic of a soft jaw we use to hold / locate a similar part.